[ User word! ]

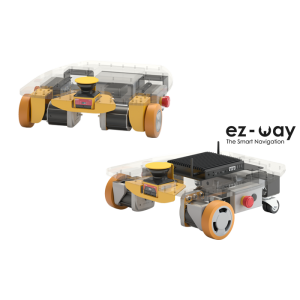

Almost two years after the discovery of ez-Wheel® solutions, Mr. Welterlin - Laboratories Technical Services Team Leader at LILLY PRODUCTION FEGERSHEIM - tells how ez-Wheel® wheels has helped to control and secure the sterilization process of their stainless steel containers.

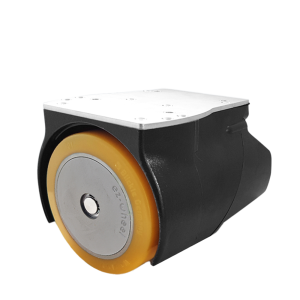

« We were looking for a solution that would make the process more secure and at the same time be flexible and compact enough to fit into a small premises, as well as ensuring adherence to environmental constraints. »

How is this process organized?

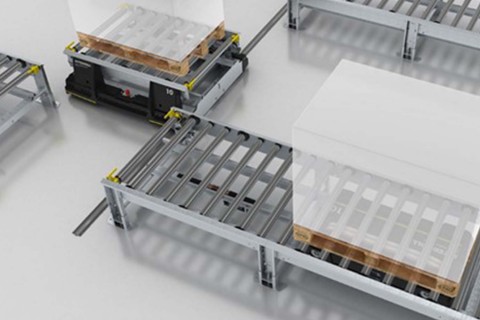

Over a complete cycle, including loading and unloading of autoclaves and return to the material preparation workshop, the electric trolleys are used for 10 to 15 minutes. 4 trolleys are used in the safety zone and 4 others are used in the aseptic zone without ever crossing each other.

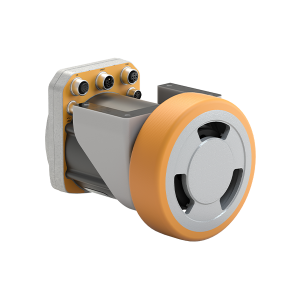

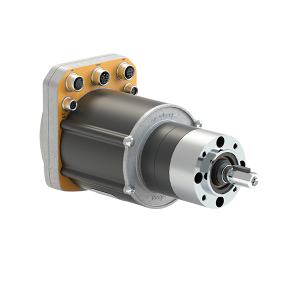

What about the wheel?

« The wheel makes the docking maneuver to the autoclave easier whilst at the same time being easier on the posture. The operator can walk beside their trolley, which can be up to 600kg (500kg for the container and almost a hundred more for the trolley), as easily as if they were operating an electric pallet truck. They can handle the load with one arm effortlessly and safely. For me, the real gain is the reduction in physical strain! »

What is the result after two years of use?

« Since the replacement of the trolley fleet in 2019, there have been no incidents relating to the overall loading and unloading, which is a great indication of success! »