[ User word! ]

Since integrating AWD® wheels into its production lines, Hitachi Construction Machinery Co., Ltd. has been evaluating the results.

Safety measures that led to substantial improvements to parts delivery lines

Safety and efficiency improvements so impressive, "people from other factories visit to see what we've done"

Left: Hasegawa-san, Right: Matsuzaki-san

Hitachi Construction Machinery Co., Ltd. is a manufacturer of high-performance hydraulic excavators, wheel loaders, dump trucks, road construction machinery, and other equipment. The company has implemented the Assist Wheel Drive system at their Tsuchiura Works facility.

For this case study, we spoke with Hasegawa-san from the TIPS Promotion Sec. and Matsuzaki-san from the Production Reform Promotion Dept. They have made significant improvements to parts transportation at Tsuchiura, the company's mother factory.

[Translated from the Japanese, original version in Japanese]

Safety measures were the catalyst for improvements. The effect was so great that workers from facilities in Japan and overseas visited to see.

First, we'll discuss the process through which Hitachi Construction Machinery Co., Ltd. adopted Assist Wheel Drive. The Tsuchiura Works facility primarily produces medium-sized hydraulic excavators (10-35 ton load limits). There are 15 models and 300 variations (specifications). Production is carried out from scratch on an assembly line over 100 meters long, with a different excavator built each time. Assist Wheel Drive was introduced as part of the assembly process for the lower rollers, which form part of the undercarriage (for crawler excavators).

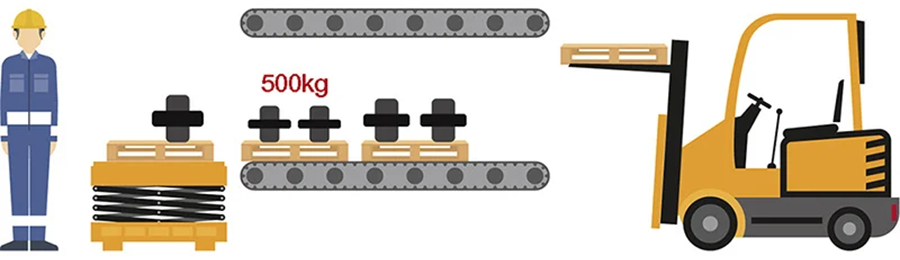

To assemble lower rollers of different sizes and weights in the same place on the line, the company previously used a dedicated pallet for each roller type. These pallets were carried by forklifts, supplied to the working side (lower level) of a two-level conveyor. After use, each pallet would be moved to the upper conveyor by a lifter and collected by a forklift. 50 pallets of roller parts for that day's production, which had been prepared at an external warehouse the previous day, were laid out flat next to the assembly area.

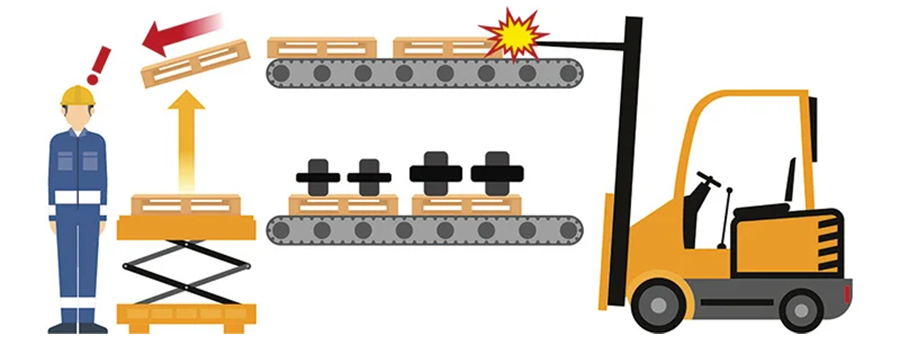

Eventually, a worker on site noticed the risk of parts falling from the upper conveyor, and contacted the TIPS Promotion Sec.

As Hasegawa-san (TIPS Promotion Sec.) explained as part of the background to Assist Wheel Drive's introduction, Hitachi Construction Machinery's basic philosophy is that "safety and health are all priorities". In fiscal 2024, the company established the Safety & Health/Compliance Group to further strengthen their health and safety management under the direct control of the president. The team carried out a risk assessment, and prioritized hardware-related safety measures.

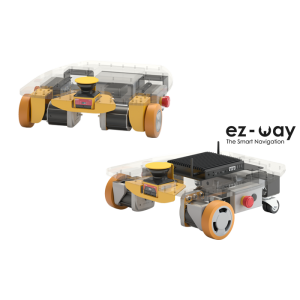

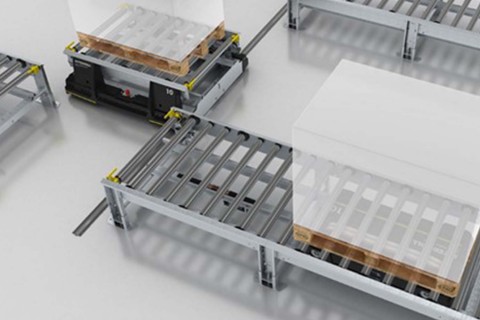

After careful consideration, the company decided to use Assist Wheel Drive to 1) supply parts loaded on a jig to the assembly line and 2) collect the jig afterwards.

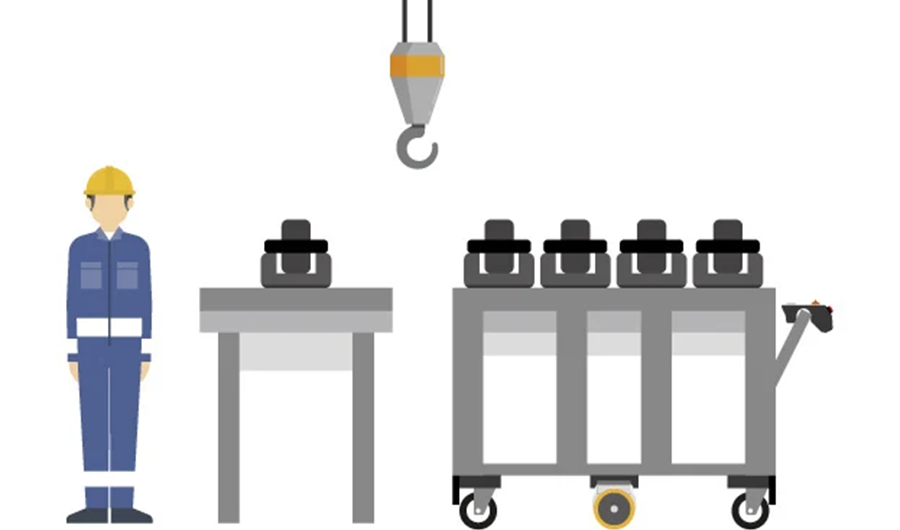

Work flow before and after implementation

① Delivery to upper and lower conveyors

With a forklift:

② Supply of parts

③ Collection of dedicated pallets

With Assist Wheel Drive:

① Supply of parts placed on a jig

② Collection of jig

The adoption of Assist Wheel Drive prompted a review of the site's work processes, jigs, transportation methods, kitting and packaging, resulting in numerous benefits (explained below).

It's easy to understand why "people from other factories visit to see what we've done".

The effects of improvement

- Disposal ofappx. 280 pallets

- Elimination of pre-picking at external warehouses (effective manpower reduction: two workers)

Previously, appx. 800 rollers were set on dedicated pallets each day using a crane

- No need for transport to return dedicated pallets to an external warehouse

Improved loading efficiency using general purpose pallets

- Work-in-process inventory reduced from 50 units to twowith lineside kitting

- Products are delivered in their original packaging, reducing the storage space needed for dedicated pallets

- As a result of the above changes, pallet delivery using forklifts has been halved

- Improved assembly work efficiency (effective manpower reduction: 0.5 workers)

Assistance products are a desired solution for transporting heavy loads. However, there are surprisingly few options

We asked why the company hadn't switched from conveyor transport to cart transport until now, given the significant improvements that can be achieved by doing so.

Hasegawa-san: "Of course, we knew that switching to cart transport would lead to benefits, such as manpower reductions and more effective use of space. However, a cart loaded with parts can weigh close to 600kg. Carrying such heavy loads with human power alone is hard physical work, and difficult to continue doing each day. From a safety perspective, without Assist Wheel Drive these improvements would not have been possible."

Matsuzaki-san (Production Reform Promotion Dept., MONOZUKURI Innovation Office) was formerly Hasegawa-san's superior. He discussed the difficulties faced during their search for a solution:

"That meant we needed to find an assistance product that could safely transport 600kg, but it was hard to find one that could handle such a heavy load. We even carried out on-site tests, but some products couldn't support the load weight even though it was within the listed specifications. It was really worrying."

"So I went to an industry event and discovered this Assist Wheel Drive system. It wasn't on sale yet at the time, but I still remember thinking 'this is the one!'" (Matsuzaki-san)

Assist Wheel Drive can handle heavy loads,and also breaks down fixed mindsets at work sites

The introduction of Assist Wheel Drive was the catalyst behind these improvements, which have produced numerous benefits. We asked Hasegawa-san about this impact and changes within the company.

"This assembly line has been running for close to 50 years, and we've made many improvements to it over time. However, many workers who do repetitive work every day tend to be trapped in fixed mindsets and believe "the way things are is only natural". We hope that, by making improvements that break fixed mindsets in this way, we'll see an increase in requests and insights from workplaces that are free from those mindsets."

"We wouldn't have achieved these things if we hadn't found Assist Wheel Drive, which is capable of transporting heavy loads. That was thanks to the TIPS Promotion Sec., which carried out a thorough search and came up with this solution.

In particular, Assist Wheel Drive does not require any qualifications to operate, unlike forklifts. Being able to transport heavy loads regardless of qualifications, age, gender, or experience is extremely helpful at workplaces such as ours, where many workers handle heavy loads. Moving forward, we are accelerating our efforts to further reduce the amount of heavy physical work."

Hasegawa-san is keen to expand on the success of Assist Wheel Drive at the mother factory by introducing it at facilities in Japan and overseas.

Hitachi Construction Machinery Co., Ltd.

Hitachi Construction Machinery Co., Ltd. is a manufacturer of high-performance hydraulic excavators, wheel loaders, dump trucks, road construction machinery, and other equipment. The company is the third largest construction machinery business in the world, with a strong global reputation built on the diverse product lineup's safety, reliability and durability. Hitachi Construction Machinery has seven production facilities in Japan that work to global standards. They also carry out localized production in the Netherlands, India, Indonesia, China, Canada, and other countries.

TIPS Promotion Sec.

TIPS* is a term invented by Hitachi Construction Machinery, used within the company to describe internal activities. It refers to a production method that brings innovation, originality and ingenuity together. Specifically, this department takes up concerns from workers at production sites, determines their importance level, and drives improvement. These activities are wide-ranging, including safety measures, improvements to productivity, reducing work-in-process inventory, and reviews of logistics.

* Total Innovative & Inventive Production System: a production method that combines "innovation" with "originality and ingenuity".

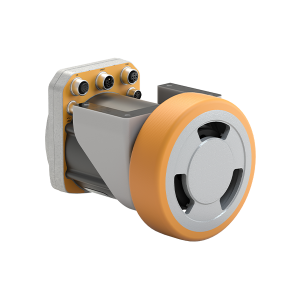

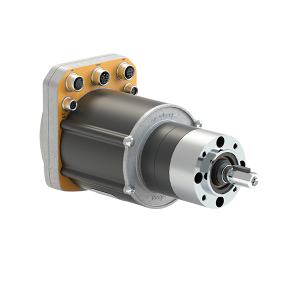

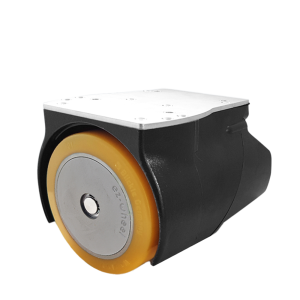

La gamme AWD® Assist Wheel Drive

| By integrating the motor, batteries, and electronics, the AWD® range offers a simple and efficient solution to quickly add electric assistance to any rolling equipment.Designed to simplify mechanical integration, this compact electric wheel is a fast and easy option compared to other alternatives. |