-

Products

Products

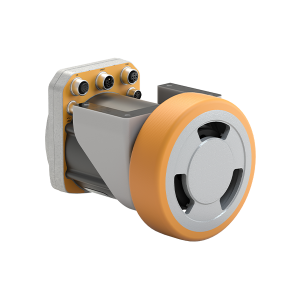

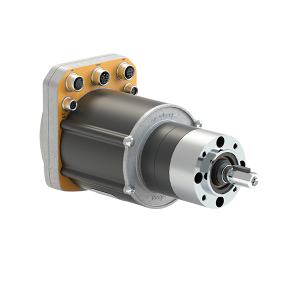

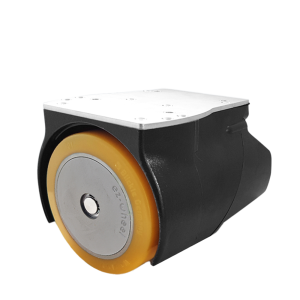

BackAUTOMATION – Safety Wheel DriveASSISTANCE – Assist Wheel Drive

-

Assistance

Assistance

BackIndustryProduction cycle optimization.

Adding an electrical motorization on manual handling equipment allows improving production cycle while preserving the health of operators. Motorize any rolling equipment in industry such as heavy load carriers, industrial hand trucks or special machinery.![Visuel domaine industry]() AutomotiveLogistics flow optimization.

AutomotiveLogistics flow optimization.

Adding an electrical motorization on manual handling equipment allows improving logistics flow while preserving the health of operators. Motorize any rolling equipment in automotive industry such as milk run trolleys, towed trailers or kitting trolleys.![Visuel domaine automotive]() Food processingHandling optimization in harsh environments.

Food processingHandling optimization in harsh environments.

Adding an electrical motorization on manual handling equipment allows improving inter-units logistics while preserving the health of operators. Motorize any rolling equipment in food processing industry such as pusher/pullers of DIN9797 tanks, stainless steel tanks or drum trolleys.![Visuel domaine food processing]() Logistics / RetailSupport the production rate increase.

Logistics / RetailSupport the production rate increase.

Adding an electrical motorization on manual handling engine allows supporting the production rate increase while preserving the health of order picker. Motorize any rolling equipment in logistics and retail sector such as order preparation trolleys, picking trolleys or pusher/puller.![Visuel domaine logistics retail]() MedicalHealthcare workers support.

MedicalHealthcare workers support.

Adding an electrical motorization on manual handling equipment allows preserving the health of healthcare workers.

Motorize any rolling equipment in medical sector such as patient transfer, laundry trolleys, pusher/puller, catering trolleys…![Visuel domaine medical]() PharmaceuticalFor an efficient and safe manual handling.

PharmaceuticalFor an efficient and safe manual handling.

Adding an electrical motorization on manual handling equipment allows preserving the health of pharmaceutical workers and improving productivity. Motorize any rolling equipment operating in pharmaceutical sector such as stainless-steel tanks, picking trolleys, drum trolleys.![Visuel domaine pharma]() EntertainmentClean and quiet mobility solution.

EntertainmentClean and quiet mobility solution.

Adding an electrical motorization on manual handling equipment or vehicle facilitates and optimizes every trips.

Motorize any rolling equipment in entertainment sector such as stage machinery, food carts, street trolleys, parade floats.![realisation serie 300I parade float]() OutdoorDaily green mobility.

OutdoorDaily green mobility.

Adding an electrical motorization on rolling equipment or vehicles facilitates and optimizes every daily trip while preserving environment. Motorize any rolling equipment used in public spaces such as street trolleys, land drone, delivery carts.![realisation serie 10 agricultural drone]()

-

Automation

Automation

BackIndustrial automationAutonomous mobile production tools.

SWD® solutions make all the production equipment of the Factory of the Future mobile and autonomous on the move, regardless of their size and operating cycles.![! Automatisation industrielle]() Warehouse RobotisationMeans for automated logistics.

Warehouse RobotisationMeans for automated logistics.

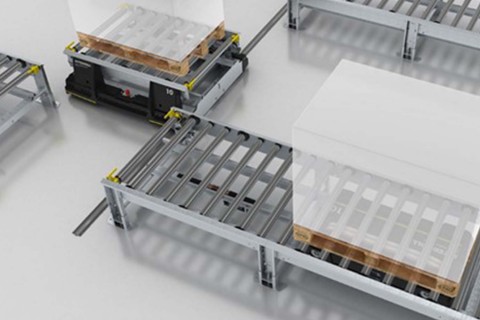

SWD® solutions enable the automation of all order picking, Good-to-Man, automated storage or pallet and package conveying applications for the modern logistics warehouse.![! Robotisation entrepots]() Industrial transitionTools for automated load transfer.

Industrial transitionTools for automated load transfer.

SWD drives can be adapted to all load transfer axis automation needs in intralogistics, with a minimum of development and integration effort. The certified safety control bricks accelerate the market introduction of innovative solutions that comply with applicable regulations.![! Transitique industrielle]() Collaborative RobotAGV, AGC and AMR development accelerator.

Collaborative RobotAGV, AGC and AMR development accelerator.

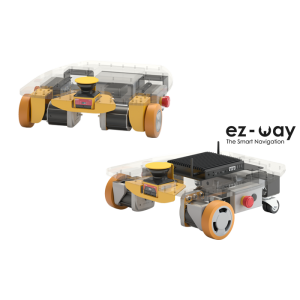

The new SWD® technology allows to robotize a rolling machine with only 3 components: two SWD® wheels and a safety scanner. The engineering effort to develop a safety compliant mobile robot is drastically reduced and can cut development costs by a factor of 5, and the absence of bulky components offers complete freedom of robot layout and shape.![! Robots collaboratifs]()

-

Newsroom

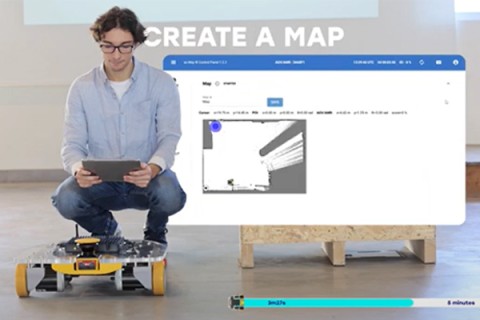

![SK ez Way]() [Unboxing] SWD Starter Kit with ez-Way®Unpack your product and start a mission in just 5 minutes!> Read more

[Unboxing] SWD Starter Kit with ez-Way®Unpack your product and start a mission in just 5 minutes!> Read more - Contact